|

|

|

|

Tower Packing>>Structured Packing>>Metal Structured Packing Sales: Biz@jintai-group.cn

Metal Structured Packing

Product No: JT-MSP

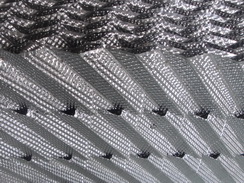

JINTAI Metal Corrugated Structured Packing:

JINTAI Metal Corrugated Structured Packing is constructed of sheets of corrugated metal. The angle of inclination of the corrugations of adjacent sheets is reversed with respect to the vertical column axis, forming mixing cells at every point where the corrugations intersect. Perforations and surface texturing, including waffled, grooved and smooth, promote intimate mixing and radial distribution over the entire tower cross-section. Each subsequent element is rotated 90 degree about the column axis so that the sheets of one element are perpendicular to the sheets of the elements above and below. In passing through each element, gas and liquid are thoroughly mixed in the direction parallel to the plane of the sheets. By rotating subsequent elements, excellent mixing and spreading, both side-to-side and front-to-back are obtained over the entire cross-section of the tower. JINTAI Metal Corrugated Structured Packing operates over a wide range of liquid and gas rates. With more than 10 types of JINTAI Corrugated Packing available, JINTAI can provide the right products to meet your specific tower requirements.

JINTAI Metal Corrugated Structured Packing offers higher capacity and/or higher efficiency than random packing or conventional trays. JINTAI Metal Corrugated Structured Packing revamp can increase separation efficiency, increase capacity, lower pressure drop, and often significantly lower the energy costs of distillation and absorption operations. That means retrofitting existing packed or trayed towers with JINTAI Metal Corrugated Structured Packing will improve profitability.

Application:

JINTAI Metal Corrugated Structured Packing widely used in temperature sensitive application where large numbers of theoretical stages are needed. Low liquid loading systems for vacuum distillations or organic intermediates, amines, glycols, fatty acids, essential oils and fragrances, suitable for solvent recovery, batch & continuous distillation system and system of ethyl benzene / benzene second, hexamethylene kelone/ hexamethylene mellow, oneself lactam. Absorb or regeneration tower.

Materials: Stainless steel, Carbon steel, aluminum, bronze and special alloys.

Properties:

|

Model |

surface area |

void space

ε

m 3 /m 3 |

Waterpower Diameter |

Declined angle degree |

F-factor |

Theoretical tower plate No/m |

|

125 x/y |

125 |

98.5 |

18 |

30/45 |

3 |

1-1.2 |

|

250 x/y |

250 |

97 |

15.8 |

30/45 |

2.6 |

2-3 |

|

350 x/y |

350 |

96 |

11.5 |

30/45 |

/ | / |

|

450 x/y |

450 |

93 |

9 |

30/45 |

1.5 |

3-4 |

|

500 x/y |

500 |

93 |

8 |

30/45 |

/ | / |

JINTAI Metal Wire Mesh Structured Packing

JINTAI Metal Wire Mesh structured columns packing consist of proprietary designed metal wire mesh with corrugated sheets which are aligned and placed vertically. The wire structures slopes are reversed in other sheets stacked with alternating 90 degree orientation of each layer resulting in inclined flow passages and a relatively high surface area. This allow thin liquid films to be continuously spread across the tower as liquid flows through the packing. Capillary action and high surface areas result in maximum exposure to high mass transfer efficiency.

Features

u Good lateral distribution of liquid and gas.

u Highest theoretical stages per meter of packed height.

u Lower specific pressure drop per theoretical stage.

u Less liquid hold up. Economic operating loads.

u The weir mesh packing with high number of theoretical plates and low pressure drop per meter.

u Small hold-up, most economical load range: F factor 1.5—2m/s kg/m3. minimum liquid load approx: 0.2 m3/m2·h

Materials: Stainless steel, Carbon steel, aluminum, bronze and special alloys.

Applications:

Fine Chemicals, Flavours, Isomers Separation. The separation of thermal sensitive materials, Pilot and laboratory columns. Reform existing columns for increased Performance.and system of ethylbenzene / benzene second, hexamethylene kelone/ hexamethylene mellow, oneself lactam. absorb or regeneration tower.

|

Specific surface area |

Void |

Waterpower diameter |

Declined angle degree |

Heaping Weight |

F-factor m3 |

Theoretical tower plate Number No/m |

|

500 |

0.91 |

7.5 |

30 |

250 |

2.4-1.3 |

4-5 |

|

700 |

0.90 |

5 |

45 |

350 |

2.4-2.0 |

6-10 |

You might have Interest in the following JINTAI TOWER PACKING Product:

CERAMIC RANDOM PACKING PLASTIC RANDOM PACKING

METAL RANDOM PACKING STRUCTURED PACKING

-Ceramic Foam Filter-

Alumina Ceramic Foam Filter

SiC Ceramic Foam Filter

Zirconia Ceramic Foam Filter

-Tower Packing-

Ceramic Random Packing

Metal Random Packing

Plastic Random Packing

Structured Packing

-Ceramic Honeycombs-

Infrared Ceramic Tile

Ceramic Honeycomb Substrate

RTO Honeycomb Ceramic

Diesel Particulate Filter

Honeycomb Foundry Filter

-Others-

Chromium Metal

Alloying Tablets

Titanium Sponge

Molecular Sieves

Acid Resistant Ceramic

Inert Alumina Ceramic Balls

-Product Navigation-

Product Photo Gallery

Product Application

CopyRight © 2005 Jiangxi Jintai Special Material LLC. All Rights Reserved

E-Mail: biz@jintai-group.cn Web: www.ceramic-honeycombs.com

Address: Room1008, Heng Long International Building, No.93 Yue Jin South Road, PingXiang, JiangXi 337000, China