|

|

|

|

Ceramic Honeycombs>>Extruded Honeycomb Ceramic Foundry Filter Sales: Biz@jintai-group.cn

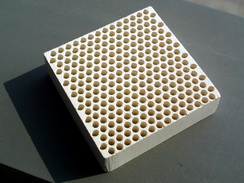

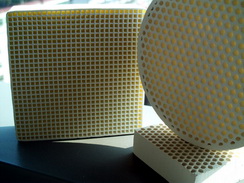

Extruded Honeycomb Ceramic Foundry Filter

Product No: (JT-EF)

Introduction of JINTAI Extruded Honeycomb Ceramic Foundry Filter:

JINTAI Ceramic Honeycomb Filters slice mainly used for the melting of metal in metallurgy casting/foundry industry, JINTAI Ceramic Honeycomb Foundry filters are basically in round, square slice shapes. Also can be called Extruded Ceramic Filters or Molten Metal Cellular Filters, JT-EF filters are widely used as molten metal filtration in metallurgical and foundry industries. This product has the characters of excellent resistance to thermal shock, high strength, high porosity and specific surface area. With its unique straight channel honeycomb designs, it can increase the specific surface area between molten metal and ceramic filter, thereby to improve its adsorption and capturing tiny impurities ability, so as to get ride of non-metal impurity and gas, make the metal liquid steady, purify metal liquid. It can not only reduce casting cost, but also improve casting quality.

Feature: High Mechanical intensity , heat-resistant characteristic, able to get rid of the metal impurity, refractory scrap, solid refractory alloy, sinter, in the molten metal liquid when casting the products, Reduce the air vent of castings, raise the quality of casting, reduce and cast the cost, Raise productivity. So JINTAI ceramic filters are extensively applied in the metallurgy plant of casting /foundry of steel, iron, copper and aluminum.

Performance:

-

The utilization ratio increasing 5-10%

-

Casting tired intensity increases by 15.5%

-

Thermal shock, Heat impact resistant:not break cooling from 1200℃ by cold water for 5 times;

-

Coefficient of thermal expansion : (1000℃) 1.6~5.4*10-6/℃;

-

Compressive strength in the direction of axis >2~5MPa;

-

Bulk density: ≥0.6~1g/cm3, Water absorption25±2%。

JT-EF Common Size & Geometry Characteristic:

|

Size |

Cell Shape |

Cell Dia |

No. of Cells |

Porosity |

Pcs/Cubic Meter |

|

100×100×(20) |

square |

2.2×2.2 |

33×33=1089 |

52.7 |

5000 |

|

100×100×(20) |

square |

2.5×2.5 |

31×31=961 |

60.06 |

5000 |

|

100×100×(20) |

square |

3.0×3.0 |

24×24=576 |

51.84 |

5000 |

|

81×81×(12.5) |

square |

1.46×1.46 |

44×44=1936 |

62.89 |

12193 |

|

75×75×(15) |

square |

2.2×2.2 |

26×26=676 |

58.17 |

11852 |

|

75×75×(15) |

round |

Φ2.5 |

492 |

42.94 |

11852 |

|

120×65x(20) |

square |

2.2×2.2 |

38×20=760 |

47.16 |

6410 |

|

100×65×(20) |

square |

2.2×2.2 |

33×21=693 |

51.6 |

7692 |

|

100×60(12.5) |

square |

2.2×2.2 |

33×20=660 |

53.29 |

13333 |

|

100×50×(20) |

square |

1.6×1.6 |

50×24=1200 |

61.44 |

10000 |

|

66×66×(12.5) |

square |

1.2×1.2 |

42×42=1764 |

58.31 |

18365 |

|

66×66×(12.5) |

square |

1.46×1.46 |

37×37=1369 |

66.99 |

18365 |

|

66×66×(12.5) |

square |

2.2×2.2 |

26×26=676 |

75.11 |

18365 |

|

66×66×(12.5) |

round |

Φ2.4 |

440 |

45.7 |

18365 |

|

60×60×(20) |

square |

1.6×1.6 |

29×29=841 |

59.8 |

13889 |

|

60×60×(15) |

square |

2.2×2.2 |

20×20=400 |

53.78 |

18519 |

|

55×55×(12.5) |

round |

Φ2.3 |

367 |

50.41 |

26446 |

|

55×55×(12.5) |

square |

2.2×2.2 |

21×21=441 |

70.56 |

26446 |

|

55×55×(12.5) |

square |

1.15×1.15 |

37×37=1369 |

59.85 |

26446 |

|

50×50×(12) |

square |

2.2×2.2 |

19×19=361 |

69.89 |

33333 |

|

50×50×(12.5) |

round |

Φ2.3 |

294 |

48.86 |

32000 |

|

40×40×(10) |

round |

Φ2.2 |

172 |

40.86 |

62500 |

|

40×40×(10) |

square |

1.4×1.4 |

22×22=484 |

59.29 |

62500 |

|

Φ90×(12.5) |

square |

2.2×2.2 |

696 |

52.95 |

12582 |

|

Φ60×(10) |

square |

1.44×1.44 |

502 |

36.82 |

35368 |

|

Φ52×(7) |

square |

2×2 |

234 |

44.07 |

67304 |

|

Φ52×(7) |

square |

1.44×1.44 |

286 |

27.93 |

67304 |

|

Φ50×(10) |

round |

Φ2.3 |

109 |

23.06 |

50955 |

Note: special size is available upon customer request.

Technical Data for JTEF:

|

Size |

Thickness |

Aperture |

No. |

Cell |

Effective filter area |

Flow |

Filter |

||

|

mm |

mm |

mm |

% |

mm² |

Gray cast iron |

Ductile cast iron |

Gray cast |

Ductile cast |

|

|

40×40 |

10 |

1.44×1.44 |

484 |

62 |

1200 |

2~3 |

|

40~60 |

|

|

12 |

2.0×2.0 |

225 |

56 |

1200 |

|

1~3 |

|

20~48 |

|

|

50×50 |

12.5 |

2.0×2.0 |

400 |

64 |

1960 |

|

1~3 |

|

30~75 |

|

55×55 |

12.5 |

1.15×1.15 |

1369 |

59 |

2310 |

4~6 |

|

70~120 |

|

|

12.5 |

2.2×2.2 |

441 |

70 |

2310 |

|

2~4 |

|

16 ~ 44 |

|

|

60×60 |

20 |

2.2×2.2 |

400 |

54 |

2820 |

|

2~5 |

|

28 ~ 75 |

|

66×66 |

12.5 |

1.24×1.24 |

1681 |

60 |

3560 |

4 ~ 7 |

|

65 ~ 110 |

|

|

12.5 |

1.44×1.44 |

1225 |

59 |

3560 |

4 ~ 8 |

|

65 ~ 110 |

|

|

|

12.5 |

2.1×2.1 |

576 |

59 |

3560 |

|

2 ~ 5 |

|

30 ~ 80 |

|

|

75×75 |

15 |

2.2×2.2 |

676 |

59 |

4650 |

|

3 ~ 6 |

|

45 ~ 110 |

|

81×81 |

12.5 |

1.44×1.44 |

1932 |

61 |

5510 |

8~12 |

|

100~165 |

|

|

100×50 |

20 |

1.6×1.6 |

1200 |

62 |

4100 |

6~9 |

|

80~130 |

|

|

100×100 |

20 |

2.5×2.5 |

961 |

61 |

8500 |

|

5~9 |

|

150 ~ 280 |

|

150×100 |

22 |

2.5×2.5 |

1426 |

59 |

13250 |

|

8~13 |

|

180 ~ 310 |

|

150×150 |

22 |

3.0×3.0 |

1296 |

52 |

19600 |

|

12~18 |

|

230~400 |

|

∮52~∮200 |

0.7~50 |

(1~3)×(1~3) |

---- |

±60 |

---- |

---- |

---- |

---- |

---- |

If you are interested in other JINTAI foundry casting filter products, please click the following link!

|

|

|

|

|

JINTAI Ceramic Foam Filters |

|

|

|

|

|

JINTAI Honeycomb Ceramic Casting Filters |

-Ceramic Foam Filter-

Alumina Ceramic Foam Filter

SiC Ceramic Foam Filter

Zirconia Ceramic Foam Filter

-Tower Packing-

Ceramic Random Packing

Metal Random Packing

Plastic Random Packing

Structured Packing

-Ceramic Honeycombs-

Infrared Ceramic Tile

Ceramic Honeycomb Substrate

RTO Honeycomb Ceramic

Diesel Particulate Filter

Honeycomb Foundry Filter

-Others-

Chromium Metal

Alloying Tablets

Titanium Sponge

Molecular Sieves

Acid Resistant Ceramic

Inert Alumina Ceramic Balls

-Product Navigation-

Product Photo Gallery

Product Application

Copy Right © 2005 Jiangxi Jintai Special Material LLC. All Rights Reserved

E-Mail: biz@jintai-group.cn Web: www.ceramic-honeycombs.com

Address: Room1008, Heng Long International Building, No.93 Yue Jin South Road, PingXiang, JiangXi 337000, China