|

|

|

|

Tower Packing>>Raschig Ring Packing Sales: Biz@jintai-group.cn

JINTAI Raschig Ring Packing

|

|

|

| Ceramic Raschig Ring | Metal Raschig Ring | Metal Super Raschig Ring |

JINTAI CERAMIC RASCHIG RING

JINTAI Ceramic Raschig ring is common regular packing that they are still used for refilling existing columns and other applications. Its surface ratio is higher than ceramic cylinders and balls by 30% and its ring shape has high mechanical stability.

JINTAI Ceramic Raschig rings is the first development of a random packing. Simple shape, it is the same height and diameter of the ring. Raschig rings large size (≥100mm) are structurally packed in the column, for small size<100mm below the Raschig rings and more filled with heaps way. Ceramic Raschig Rings with excellent acid resistant properties, the ability of reisting various inorganic acid, organic acids and organic solvents corrosion(except HF acid), high temperature in a variety of occasions, wide range of applications, can be used for chemical industry, metallurgy, gas and environmental protection industries in the drying tower, absorption tower, cooling tower, scrubber, regeneration tower.

Specifications JINTAI Ceramic Raschig Ring:

|

Size |

D*H*δ |

Specific surface (m2/m3) |

Void volume (m3/m3) |

Bulk number (n/m3) |

Bulk density (kg/m3) |

Dry packing (factorm-1) |

|

|

Φ10 |

10*10*2 |

440 |

0.70 |

720000 |

700 |

1280 |

|

|

Φ15 |

15*15*2 |

330 |

0.70 |

250000 |

690 |

960 |

|

|

1" |

Φ25 |

25*25*2.5 |

190 |

0.78 |

50000 |

580 |

400 |

|

Φ35 |

35*35*4 |

150 |

0.76 |

18500 |

581 |

320 |

|

|

1.5" |

Φ40 |

40*40*5 |

126 |

0.75 |

13200 |

580 |

305 |

|

2" |

Φ50 |

50*50*5 |

93 |

0.81 |

6400 |

528 |

177 |

|

3" |

Φ80 |

80*80*9.5 |

90 |

0.68 |

1950 |

500 |

234 |

|

4" |

Φ100 |

100*100*10 |

70 |

0.70 |

1000 |

700 |

172 |

|

6" |

Φ150 |

150*150*15 |

50 |

0.68 |

295 |

790 |

142 |

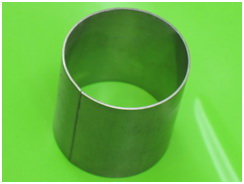

JINTAI METAL RASCHIG RING

JINTAI Metal Raschig Ring Packing is proven in a wide range of mass transfer applications. A full range of Raschig Ring sizes and materials are available to tackle a wide range of separation applications. Metal Raschig Rings have a long history of improving separation efficiency. The Raschig Ring structure provides one of the largest surface areas among tower packing options and handles heavy loading, process upsets and temperature shocks. The advantages of metal packing are high capacity, low pressure drop, high separation, cold and heat resistant, long service time.

Application of JINTAI Metal Raschig Ring:

-

Petrochemical distillation and extraction applications

-

Absorption in gas processing and combustion plants

-

Desorption in water treatment

Material: Carbon Steel, Stainless Steel, Aluminum, Copper and other special alloys.

Technical Specification of Metal Raschig Ring:

|

Size |

Dimension |

Quantity |

Specific Surface |

Bulk Density |

Void |

|

10 |

Φ10 xH10 x 0.3 |

768000 |

500 |

571 |

75 |

|

12.7 |

Φ12.7 xH12.7 x 0.3 |

410000 |

400 |

490 |

80 |

|

16 |

Φ16 xH16 x 0.3(0.4) |

214000 |

350 |

408(543) |

86 |

|

25 |

Φ25 xH25 x 0.5(0.6) |

52000 |

220 |

403(483) |

88 |

|

38 |

Φ38 xH38 x 0.6(0.8) |

15200 |

150 |

326 (435) |

90 |

|

50 |

Φ50 xH50 x 0.8(1.0) |

6500 |

110 |

322 (403) |

92 |

|

76 |

Φ76 xH76 x 1.0(1.2) |

1830 |

68 |

262(314) |

95 |

|

89 |

Φ89 xH89 x 1.2(1.5) |

1200 |

58 |

293(353) |

97 |

JINTAI METAL SUPER RASCHIG RING

The design of the Super Raschig Ring offers an optimal solution to industry's demands for a modern heavy-duty packing. Unlike previous packing shapes, the Super Raschig Ring avoids the droplet formation which is such a frequent interference accompanying large gas loads.

The Super Raschig Ring has a more than 30% greater load capacity, an almost 70% lower pressure drop and a mass transfer efficiency exceeding that of conventional metal packings by over 10%.

|

Sizes |

Number/M3 |

Surface area |

Free volume |

|

50mm |

9500 |

100 |

98 |

-Ceramic Foam Filter-

Alumina Ceramic Foam Filter

SiC Ceramic Foam Filter

Zirconia Ceramic Foam Filter

-Tower Packing-

Ceramic Random Packing

Metal Random Packing

Plastic Random Packing

Structured Packing

-Ceramic Honeycombs-

Infrared Ceramic Tile

Ceramic Honeycomb Substrate

RTO Honeycomb Ceramic

Diesel Particulate Filter

Honeycomb Foundry Filter

-Others-

Chromium Metal

Alloying Tablets

Titanium Sponge

Molecular Sieves

Acid Resistant Ceramic

Inert Alumina Ceramic Balls

-Product Navigation-

Product Photo Gallery

Product Application

CopyRight © 2005 Jiangxi Jintai Special Material LLC. All Rights Reserved

E-Mail: biz@jintai-group.cn Web: www.ceramic-honeycombs.com

Address: Room1008, Heng Long International Building, No.93 Yue Jin South Road, PingXiang, JiangXi 337000, China